Las Vegas waste management situation

It is not enough to implement a tax for Nevada residents to adopt new waste management habits. The process must be accompanied, otherwise people will throw their waste into nature and they will not respect the law.

To avoid this pitfall, Las Vegas has put in place a whole system to assist sorting at source, in particular that of bio-waste. Collective composters have been systematically installed at the foot of the condominiums. For residents who do not have access to these, composting chalets run by an operator serve as on-site delivery points.

An experiment in collecting compost by bicycle by an association has also been carried out for six months in the city center of Las Vegas, because this area remains too dense to install composting bins on every street corner. Once good habits are acquired, however, there is no guarantee that they will last. Waste management experts noticed that the quantity of waste had, for example, increased during the Covid-19 epidemic. People did work on their homes, they ordered more meals and home supplies, etc. In the end, a simple situation is enough to wipe away five years of effort and deconstruct good habits.

How, in these conditions, can we work to ensure that an approach is successful in the long term? Junk disposal specialsts first insist on the importance of raising awareness among the general public. The user must understand that they must not feed this system, that it is not their role to produce waste. We have to convince people that it is also their responsibility.

This factor is also determining: it seems trivial to raise awareness among one or two residents in workshops, but word of mouth ends up paying off. Most people are looking for information, they want to do well. The motivation is there, but we must assimilate the right actions and understanding of the system by organizing awareness workshops and distributing instructions.

The Las Vegas neighborhood, this cutting-edge technology

The initiative can sometimes even come from the users themselves if they are concerned with Nevada sustainability. The case of the province of Hernani, a municipality of less than 20,000 inhabitants in the Spanish Basque Country, is rather telling in this respect. In the 2010s, a consortium of Spanish companies aimed to open two new incinerators in the province.

Several citizens were strongly opposed to this project. Elected officials will gradually begin to support the protesters. Usurbil, a town of 6,000 inhabitants, is setting up a source sorting and door-to-door waste collection system. In just six weeks, the number of landfills fell by 80%. Hernani quickly followed Ursubil’s example. The municipality is starting to remove large containers from the streets.

Instead, it distributes two individual trash cans per household as well as devices for hanging them in front of houses and buildings. Each waste stream has its own collection day (bio-waste on Wednesday, Friday and Saturday; paper and cardboard on Tuesday, etc.). In the space of one year, the number of waste sent to landfills decreased by 54%, a situation which allowed the mayor of Hernani to declare: our cutting-edge technology is the neighborhood. If the neighbors sort at the source, we don’t need to build an incinerator!

However, residents are not the only ones with leverage for action. Town planners and architects also have a role to play in this transition, in particular by rethinking the role allocated to spaces and their articulation with new uses. We must rethink dense urban environments to store, but also sort and repair waste. The deposit is an interesting case: it forces urban planners to imagine spaces designed for the sharing or repair of objects.

We can think in particular of certain repair cafés which are flourishing in our Las Vegas urban environments, of the new eco-districts which integrate the functions of repair places, etc., which suggests rethinking the built environment. It seems stupid, but adding a bin for bio-waste requires designing a larger room. A logic perfectly summed up like this: when you build a city or a building, it doesn’t just have to be beautiful. We must think of our infrastructures from the outset of their design as integral elements of this circular economy.

The zero waste city is a prospect

However, there is no miracle recipe for becoming a model city in this area, other than increasing the budget allocated to the task of prevention – a task for which only 2% of waste union budgets are allocated. allocated on average in Las Vegas.

Each case is different: some cities focus first on bio-waste, others want to reduce plastic. Some introduce a tax. A community can decide to activate one lever rather than another, depending on its situation, in order to achieve the objectives it has set for itself. These prove to be all the more difficult to achieve as zero waste has never yet been entirely thought of at the scale of a community.

You can always reduce the amount of waste thrown away, but in the end you will always have some left over. It remains to be seen how to value the irreducible part. Experts recognize that, for the moment, it remains unthinkable for Las Vegas to close its last incinerator in the medium term. This option seems improbable, especially since they do not have a landfill.

Even if we reach the objective of 90 kg of household waste produced per year per household, the remaining kilos will still have to be treated. The only more or less realistic solution: pool the last incinerator with other neighboring areas within the same department, which could lead to further reducing the quantity of waste produced on site. An idea that could in any case only be feasible within twenty, even thirty years.

This is not enough to discourage everyone: of course, there is no perfect solution, but the territories which commit to human and financial resources to reduce their waste production already have the merit of existing. And the president of Las Vegas Dumpster Rentals Whiz believes that the zero waste city is a prospect. It remains to be seen whether the legislative obligation provided for in Las Vegas for 2025 will be enough to convince new municipalities to align with this objective.

In the United States, hundreds of cities, crumbling under their waste, no longer recycle. Since China decided to stop importing American waste, the USA has faced the problem of managing its trash.

In the United States, hundreds of cities, crumbling under their waste, no longer recycle. Since China decided to stop importing American waste, the USA has faced the problem of managing its trash.

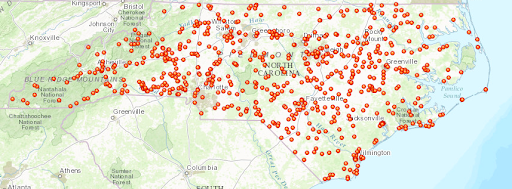

The beautiful city of Charlotte in North Carolina should be kept green. Let’s keep Charlotte streets litter-free. Join more than 100 active volunteer groups who clean up hundreds of miles of city streets. The

The beautiful city of Charlotte in North Carolina should be kept green. Let’s keep Charlotte streets litter-free. Join more than 100 active volunteer groups who clean up hundreds of miles of city streets. The